Case Study: How we helped ROBE pack lights sustainably

If you sell products worth hundreds of thousands of crowns and send them around the world, safe packaging is extremely important. But how to do this, if the packaging is also supposed to be environmentally friendly and compliant with PPWR? We have developed an environmentally friendly solution for fixing goods in packaging that is much more efficient than polystyrene.

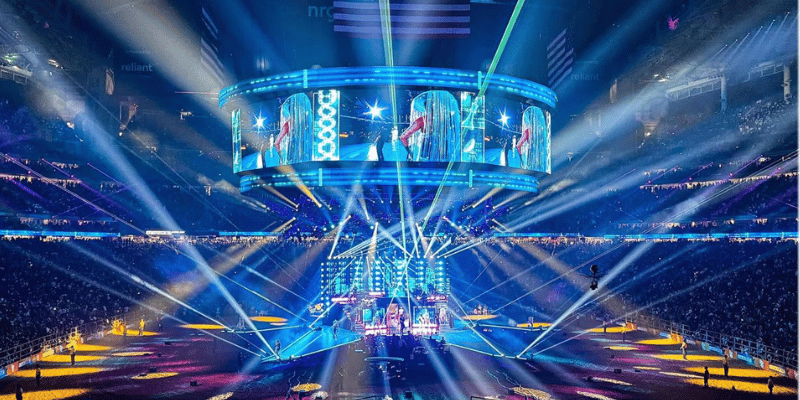

ROBE lighting s.r.o. is a Czech manufacturer of professional lighting equipment. In Valašské Meziříčí and Karviná, it produces lights that illuminate the world’s biggest events. You could see their glow at the Eurovision Song Contest and on the Eiffel Tower during the Olympics.

Primary goal: carbon footprint reduction

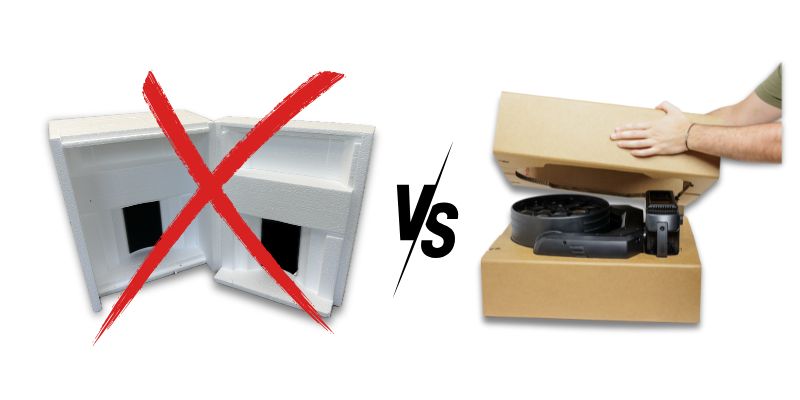

ROBE cares very much about the environment and strives to reduce its carbon footprint. Instead of the original packaging made of polystyrene and plastic, it therefore looked for a new solution. Packaging made of sustainable materials that would reliably protect their products – lights worth several tens to hundreds of thousands of crowns that they ship around the world.

However, it was not a simple task. ROBE produces a large number of different types of lights with significant variability in volumes. They were therefore looking for a manufacturer that would be able to supply even small series of packaging adapted to the shape of each light. The secondary objective was also to achieve logistics and storage savings.

Development of optimal packaging

The packaging solution was developed gradually, with attention to every detail. The process involved many changes, modifications, stress and drop tests, even under the extreme conditions achieved both in a climate chamber and in real testing during transport by aircraft.

In the end, with the help of modern digital technology we successfully managed to make packaging with fixing elements from corrugated cardboard and cardboard sheet that completely surpassed the original polystyrene solution. In terms of the safety of goods during transport and in terms of logistics and storage costs.

Better results than polystyrene?

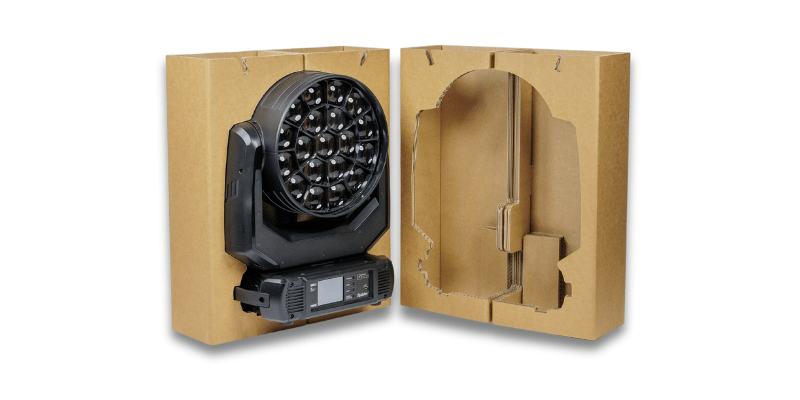

The packaging is made from strong kraft corrugated cardboard with a high grammage. This makes it much more resistant to shocks and also able to absorb moisture, which in the original polystyrene solution condensed on the product, a problem that occurs especially in air transport. Thanks to the flexibility of corrugated cardboard, we achieved better results even in the fall tests than polystyrene, which cracked and therefore lost its protective properties.

The design of the cardboard sheet fixing elements is of the “shell” type. This means that the exact shape of the fixing elements copies the product’s curves, creating a protective carapace, a kind of shell, around it. The product is therefore securely fixed and supported at several points, which, when falling, prevents it from “collapsing into itself”, meaning it is damaged by its own weight.

You can read more about development and testing in our article How to replace polystyrene fixing elements for packaging goods in an eco-friendly way according to PPWR.

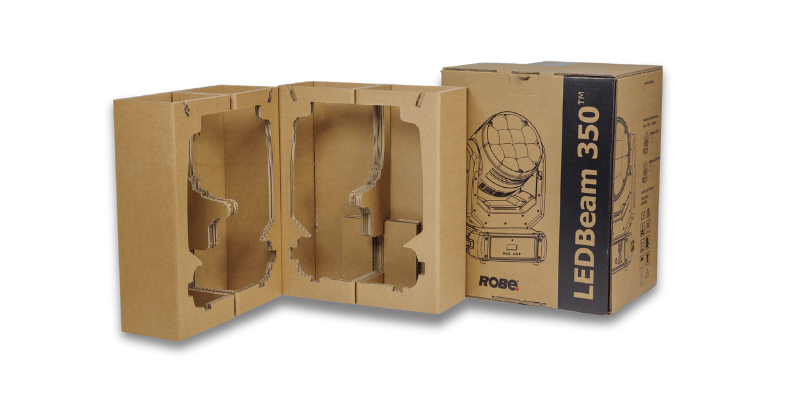

ECO Printing

Last but not least, the graphic redesign of the outer packaging has been completed. The original full-color print has been replaced by a minimalist design that aligns with the ecological concept of the packaging solution. Most of the box is printed in black, complemented by colorful details – a red dot representing the ROBE lighting logo and a green print on the back side of the packaging. The green section is dedicated to customer education and explains the overall redesign of the packaging with the aim of reducing the environmental impact.

This is also confirmed by the well-known FSC® C-188297 certification, the label for which is included in the packaging design. For products labelled in such a way, the customer can be sure that the materials used for the packaging come from forests that are managed in a sustainable and environmentally friendly way.

With digital printing, even in small series, we can easily ensure that each type of light has a different print design, which also makes it easier to distinguish them and help warehouse staff get oriented. But that’s not all.

Significant cost reductions

At the same time, thanks to the delivery of packaging and fixing elements in the unfolded state, there is a significant saving of space both in storage and in transport, which significantly reduces costs and the carbon footprint. Compared to the original polystyrene fixing elements, the space saving was ten-fold.

The packaging is both easy to fold and unfold. This allows it to be reused or easily disposed of and recycled. The entire packaging is made of corrugated cardboard, which is much more suitable for recycling than polystyrene.

Are you looking for an environmentally friendly and safe replacement for polystyrene and plastic fixing materials?

Do you want a packaging solution that protects your products and complies with PPWR?

Contact us. We will be happy to help you develop tailored sustainable packaging solutions.