How to replace polystyrene fixing elements for packaging goods in an Eco-Friendly Way according to PPWR?

Is your company also trying to be more environmentally friendly and reduce the use of plastics and polystyrene, and package in compliance with PPWR? Great. We will advise you on how to effectively replace polystyrene fixing elements with a more sustainable material that we have been working on recently and will show you the results of stress tests. You’ll be pleasantly surprised.

How does EU legislation regulate this, and what is PPWR?

The Packaging and Packaging Waste Regulation (PPWR) will come into effect on February 11, 2025. From this date, companies and entrepreneurs will have 18 months to adapt to the new rules, which will become mandatory on August 12, 2026.

The key requirements of PPWR include:

- Reducing plastic packaging and replacing it with more sustainable alternatives

- Increased requirements for packaging recyclability

- Mandatory use of recycled materials in new packaging

- Reducing excessive packaging and supporting reusable packaging

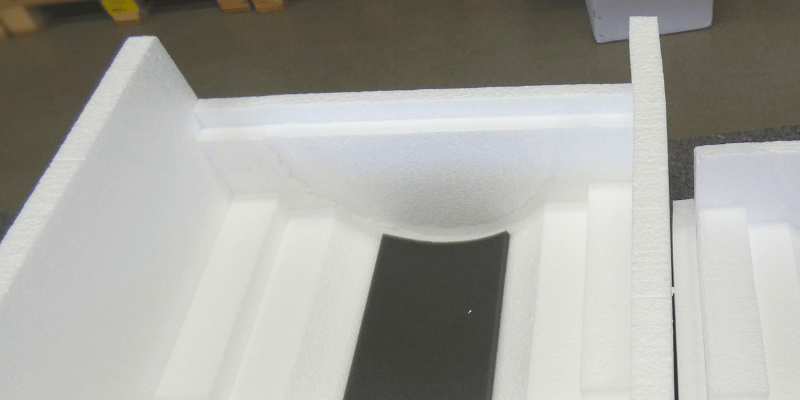

Plastic packaging, or even polystyrene inserts like the one in the picture, will soon become a thing of the past. Many businesses and companies are not waiting and are already implementing more sustainable solutions.

There is a sustainable solution

Cardboard sheet and corrugated cardboard are sustainable materials that can easily replace polystyrene fixing elements and filling. Corrugated cardboard is largely made from recycled material. It is therefore a very environmentally friendly material that, if properly designed, can even surpass standard polystyrene fixing elements with its strength and protective properties.

We have been working on developing a new innovative way to package and fix products using corrugated cardboard since 2022. The main goal was to meet all customer requirements and find a solution to fully replace synthetic materials, which are still commonly used for fixing products in packaging.

“We created the fixing elements thanks to new technical solutions and a way of processing corrugated cardboard that are not commonly used on the market. We can produce special structures with complicated shapes that do not lose their strength and are also suitable for packaging heavy objects.”

Palo Lezo, Director of Paketo group s.r.o.

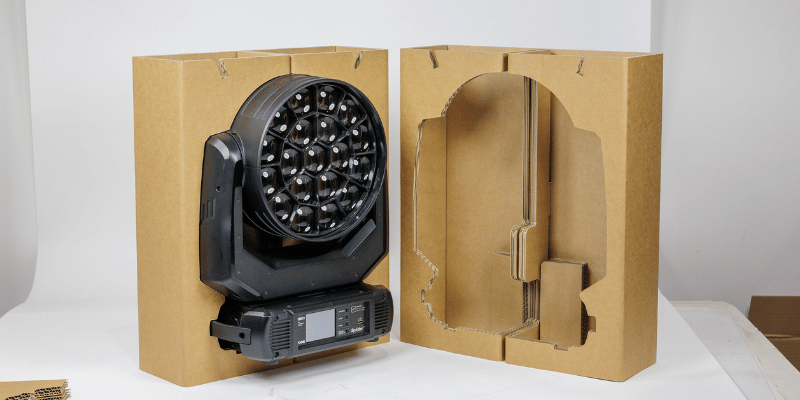

The result is protective and fixing inserts that comply with PPWR regulations. They are easy to fold and also have at least the same level of technical and safety characteristics as previously-used polystyrene or plastic fixing inserts.

We have developed two types of fixing elements:

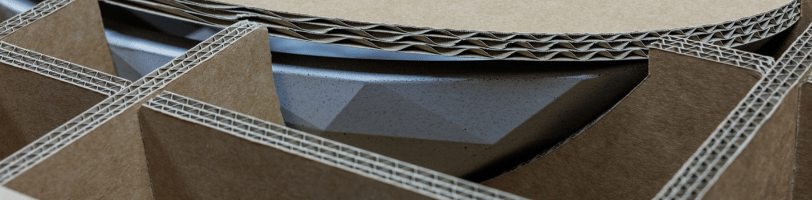

a) Grid type fixing element (PRODUCT FIT – GRID INSERT)

Fixing elements suitable for packaging and transport of products with complicated shapes and of higher and lower weight. This design meets the conditions of safe, stackable and also creative packaging that is environmentally friendly and fully replaces the original polystyrene fixing elements.

b) Shell type fixing element (PRODUCT FIT – SHELL INSERT)

This is a fixing element made of corrugated cardboard, where a precise shape cutout follows the product’s curves and forms a kind of protective shell around it, in which the product is firmly fixed. An outer box is not needed in this case, it serves only for closure and aesthetic impression.

Why is corrugated cardboard better than polystyrene?

During the development of both types of fixing structures, we carried out many stress tests in which situations that may occur in normal operation, during handling and transport of goods (falls from different heights and angles, stacking of packages on top of each other, etc.), were simulated. But we also tested extreme situations.

Safety

The results of the safety tests of our corrugated cardboard fixing elements excited our customers. At some points, we even exceeded their expectations and the protective features of their original packaging solutions.

- With polystyrene fixing elements, falls lead to cracking, thanks to which it loses its fixing and dampening properties. Corrugated cardboard fixing elements dampen and protect a product despite deformations caused by repeated falls from a height.

- During an extreme fall, a product inside a polystyrene fixing element is deformed and damaged by its own weight. Cardboard sheet fixing elements, on the other hand, held products still and prevented their deformation.

- Tests in a climate chamber first simulated the temperature conditions typical for air transport, -50°C with 0% humidity. Subsequently, the conditions changed to a temperature of +30°C with 90% humidity, which are typical for equatorial and coastal areas. Such testing is the most demanding and corresponds to the greatest extremes due to sharp changes in transport conditions. Fixing materials must cope with these conditions, if they are to be used to ship products worldwide. In our test, polystyrene fixing elements experienced undesirable water condensation directly on the product, inside the fixing element. Conversely, corrugated cardboard fixing elements absorbed moisture and, although this compromised the material’s integrity, it retained the necessary protective properties even against falls.

Saving storage costs

One great advantage of fixing materials made of cardboard sheet and corrugated cardboard is their low storage and logistics requirements. This is thanks to the ability to store fixing elements when unfolded and subsequently simply assemble the fixing elements. For example, one of our customers made a ten-fold saving on space during storage and transport compared to the original polystyrene fixing element solution.

Environmental aspects

Due to the radical reduction of fixing elements’ space requirements, especially during transport, products’ carbon footprints are also dramatically reduced. Another advantage is the high percentage of recycled material in the corrugated cardboard and the FSC® certification of all material used for the production of such protective packaging. This ensures the sustainability and renewableness of the resources used for the production of these materials and also means that they are environmentally friendly. At the same time, we have also simplified the recycling of packaging, which is completely paper-based and therefore much more suitable for recycling than polystyrene. However, end-customers can continue to use the packaging for various purposes, also thanks to the use of high-quality materials, thus extending its service life.

Original design

The design of the cardboard packaging with its corrugated cardboard fixing elements is very original and novel and creates a “wow effect” for end customers when unpacked. However, thanks to our technologies, we are able to improve the packaging solution with tailored creative printing, which will further enhance the aesthetic effect of the packaging and help to connect the packaging and the product more closely with the brand and thus strengthen the brand’s perception.

Are you looking for an environmentally friendly and safe replacement for polystyrene and plastic fixing materials?

Do you want packaging that complies with PPWR?

Contact us. We will be happy to help you develop tailored sustainable packaging solutions.