PPWR: The New EU Packaging Regulation – Why Should Businesses Act Now?

The European Union has taken another step towards a more sustainable future. The European Parliament has confirmed the PPWR proposal, which will introduce stricter rules for packaging and packaging waste management. Companies now have limited time to find functional and more sustainable alternatives for packaging their goods.

The European Union recently approved the Packaging and Packaging Waste Regulation (PPWR), which will significantly impact how companies design, use, and dispose of packaging. The regulation aims to promote a circular economy and reduce packaging and waste. PPWR came into effect on February 11, 2025, and its key requirements will be enforced starting August 12, 2026.

Key Requirements of PPWR:

- Reduction of packaging waste: The goal is to gradually reduce packaging waste by 5% by 2030, 10% by 2035, and 15% by 2040.

- Ban on certain single-use plastic packaging: From 2030, certain types of plastic packaging will be banned.

- Support of reuse: Establishing targets for reusable packaging by 2030.

- Recyclability of packaging: A requirement that all packaging must be recyclable according to strict criteria.

- Mandatory use of recycled materials: The goal is to support the circular economy. Specifically, plastic packaging must contain at least 35% recycled material by 2030.

Which Packaging Materials Does PPWR Affect?

The new regulation will impact a wide range of packaging materials across industries. Here are some examples of packaging that will need to comply with the new requirements:

E-commerce and Shipping Packaging:

- Bubble mailers and plastic postal packaging

- Polystyrene inserts and fillers

- Plastic packaging for small electronics (e.g., blister packs)

- Single-use plastic pallet wrap (stretch film)

- Packaging for cosmetics and hygiene products (e.g., plastic tubes for creams)

Retail and Industrial Packaging:

- Plastic bags for baked goods and fruits

- PVC shrink wrap on bottles (labels on PET bottles)

- Plastic packaging for pharmaceutical products

- Lightweight plastic bags (single-use bags)

Food Packaging:

- Plastic cups for beverages

- Plastic containers for fruits and vegetables (plastic trays, etc.)

- Packaging for ready-to-eat meals (foam polystyrene)

- Packaging for dairy products (e.g., yogurt cups)

If you want to study PPWR in detail, check out the full text of the European Parliament and Council Regulation on Packaging and Packaging Waste.

Corrugated Cardboard is a Sustainable Solution

Corrugated cardboard is the ideal eco-friendly alternative to plastic packaging for several reasons:

✅ Fully Recyclable and Biodegradable

- PPWR requires that all packaging be recyclable by 2030.

- Corrugated cardboard is easily and efficiently recycled – in the EU, the recycling rate for paper-based packaging exceeds 80%.

- Unlike plastic packaging, it naturally decomposes in the environment if disposed of improperly.

✅ Made from Renewable Resources

- While plastics are made from fossil-based raw materials, corrugated cardboard is produced from natural fibers and sourced from sustainably managed forests, which we guarantee with the FSC® C-188297 certification.

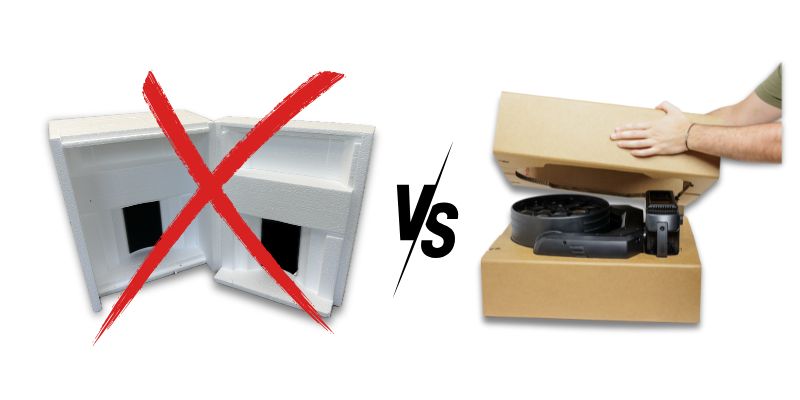

✅ Replaces Single-Use Plastics

- PPWR restricts the use of plastic fillers and cushioning materials (e.g., polystyrene fillers).

- Corrugated cardboard is an excellent alternative to plastic fillers – it even has superior protective properties compared to polystyrene.

✅ Reduces Carbon Footprint

- The production of corrugated cardboard has a lower carbon footprint than plastic packaging manufacturing.

- Its easy recyclability and reusability help companies reduce their environmental impact.

✅ Meets Recycled Content Requirements

- PPWR mandates that packaging must include a certain percentage of recycled materials – corrugated cardboard already contains between 70–100% recycled content.

- This means it complies with PPWR without requiring complex production adjustments.

✅ An Excellent Material for Packaging Any Goods

- Corrugated cardboard offers outstanding properties, such as high strength, flexibility, and the ability to absorb condensed moisture from the product, preventing damage – especially during air transportation. In stress tests, it even outperformed polystyrene.

Why Take Action Now?

Adapting to these new requirements can be time-consuming and requires careful preparation. The development and implementation of sustainable packaging solutions involve:

- Analysis of current packaging: Evaluating which packaging needs modification or replacement.

- Development: Designing a suitable corrugated cardboard structure and conducting stress tests

- Design optimization: Creating packaging that meets new standards while remaining attractive to customers.

- Implementation of new processes: Adjusting logistics processes for new packaging.

How Can We Help You?

At Paketo.one, we specialize in developing and delivering sustainable packaging solutions that comply with the latest PPWR regulations. We offer:

- Consulting and advisory services: We help you understand the new requirements and create a transition strategy.

- Custom packaging development: We design packaging that meets your specific needs while being environmentally friendly. For example, we have developed an eco-friendly alternative to polystyrene inserts for our clients.

- Testing and certification: We ensure that your new packaging meets all legislative requirements.

📖 Read our case study on how we helped a client reduce their carbon footprint through sustainable packaging.

We recommend not waiting until the new regulations take effect. Start looking for suitable, more sustainable alternatives to your packaging as soon as possible. Together, we can develop sustainable and efficient packaging solutions made from corrugated cardboard and paperboard that will comply with the new regulations while supporting your business.

Contact us, and together we will ensure that your company is ready for the future.